1. Introduction & Overview

As robotic systems grow in complexity—spanning fleets of industrial robots, autonomous drones, and service robots—their configurations become increasingly difficult to manage. Ensuring robots operate consistently across environments (lab, factory floor, field) is vital.

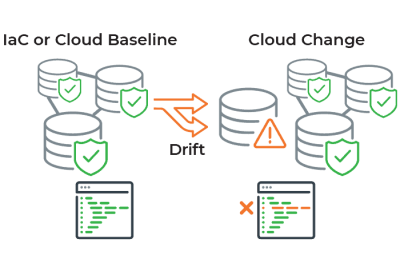

One of the most common challenges in RobotOps (Robotics Operations) is configuration drift: the divergence of a robot’s actual state from its intended or baseline configuration.

This tutorial explores Configuration Drift Detection within RobotOps, including its background, architecture, implementation, real-world use cases, and best practices.

2. What is Configuration Drift Detection?

Configuration Drift Detection is the process of monitoring, identifying, and flagging differences between a robot’s current configuration and its defined baseline or desired state.

- In DevOps, this concept applies to servers and infrastructure.

- In RobotOps, it extends to:

- Robot control software versions

- Sensor calibration parameters

- Network and communication settings

- Security credentials & firmware patches

🔹 History or Background

- Traditional IT Ops: Drift detection emerged in system configuration management (Puppet, Chef, Ansible).

- DevOps: Infrastructure as Code (IaC) tools like Terraform, Ansible, and Kubernetes adopted drift detection.

- RobotOps Evolution: With robotic systems integrating CI/CD, cloud orchestration, and AI-based decision-making, drift detection ensures that robots don’t “silently” diverge from tested configurations.

🔹 Why is it Relevant in RobotOps?

- Robots deployed in the field may self-learn, update firmware, or sync with external APIs—all of which can introduce drift.

- Misaligned configurations can lead to:

- Safety hazards (wrong calibration on industrial arms)

- Reduced efficiency (incorrect task scheduling)

- Compliance violations (security standards like ISO 10218 or NIST CSF)

3. Core Concepts & Terminology

| Term | Definition | In RobotOps Context |

|---|---|---|

| Baseline Configuration | The approved, intended system setup. | Golden firmware, validated ROS parameters. |

| Drift | Unintended deviation from baseline. | Robot installs a patch not validated by QA. |

| Drift Detection | Identifying differences from baseline. | Monitoring ROS parameter files for changes. |

| Drift Remediation | Correcting the drift. | Reapplying baseline config via automation. |

| Immutable Config | Configuration that should never change outside controlled pipelines. | Safety-critical robotic arm torque limits. |

🔹 How it Fits in the RobotOps Lifecycle

- Development – Define robot configuration baselines (YAML/JSON/ROS launch files).

- Testing – Validate configurations under simulated environments.

- Deployment – Enforce configs via CI/CD pipelines.

- Monitoring – Detect drift in real-time.

- Remediation – Auto-correct or alert teams.

4. Architecture & How It Works

🔹 Components

- Baseline Store – Git repo, CMDB, or ROS parameter registry.

- Drift Detector Agent – Runs on robot or edge node, compares live state with baseline.

- Monitoring/Alert System – Sends notifications to RobotOps dashboard.

- Remediation Engine – Restores baseline or raises incident ticket.

🔹 Internal Workflow

- Baseline config defined in Git (IaC for robots).

- Agent periodically scans the robot’s runtime state.

- Comparison engine highlights deviations.

- Drift logs → Monitoring system (Prometheus, ELK, Datadog).

- Remediation policy triggers: auto-fix, quarantine, or notify.

🔹 Architecture Diagram (text-based description)

[ Git Repository (Baseline Configs) ]

|

v

[ Drift Detection Engine ]

/ | \

v v v

[ Robot Runtime ] [ Monitoring ] [ Remediation ]

(Sensors, (Alerts, (Rollback,

ROS Params, Logs) Auto-Patch)

Firmware)

🔹 Integration Points

- CI/CD: GitHub Actions, GitLab CI, Jenkins → validate configs before deployment.

- Cloud: AWS RoboMaker, Azure Robotics → run drift scans across fleets.

- Kubernetes: Use ConfigMaps/Secrets with drift detection policies.

5. Installation & Getting Started

🔹 Prerequisites

- Robotics framework (ROS/ROS2 preferred).

- Git or other version control for baseline configs.

- Monitoring stack (Prometheus/Grafana or ELK).

🔹 Hands-On Example: Basic Drift Detection in ROS2

- Define Baseline Config (YAML)

# robot_baseline.yaml

sensors:

lidar:

range: 30

frequency: 10

controller:

speed_limit: 1.5

torque_limit: 50

- Create Drift Detection Script (Python)

import yaml, json

def load_yaml(file):

with open(file) as f:

return yaml.safe_load(f)

baseline = load_yaml("robot_baseline.yaml")

current = {

"sensors": {"lidar": {"range": 25, "frequency": 10}},

"controller": {"speed_limit": 1.5, "torque_limit": 60}

}

def detect_drift(baseline, current):

drift = {}

for key in baseline:

if baseline[key] != current.get(key):

drift[key] = {"expected": baseline[key], "actual": current.get(key)}

return drift

print(json.dumps(detect_drift(baseline, current), indent=2))

- Run & Detect Drift

python drift_detector.py

👉 Output:

{

"sensors": {

"expected": {"lidar": {"range": 30, "frequency": 10}},

"actual": {"lidar": {"range": 25, "frequency": 10}}

},

"controller": {

"expected": {"speed_limit": 1.5, "torque_limit": 50},

"actual": {"speed_limit": 1.5, "torque_limit": 60}

}

}

6. Real-World Use Cases

- Industrial Robotics – Detect miscalibration in robotic arms on assembly lines.

- Autonomous Drones – Ensure firmware and flight configurations match compliance standards.

- Healthcare Robots – Validate medical-assist robots’ security and patient interaction configs.

- Logistics Robots (AGVs/AMRs) – Prevent drift in navigation settings that may cause path errors.

7. Benefits & Limitations

Benefits

- Ensures robot safety and regulatory compliance.

- Minimizes downtime via early detection.

- Automates remediation, reducing human error.

- Enables fleet-wide configuration consistency.

Limitations

- High resource overhead if not optimized.

- False positives (acceptable changes flagged as drift).

- Requires strict baseline governance.

- Complex integration with legacy robotics systems.

8. Best Practices & Recommendations

- Automate Baselines – Store configs in Git, enforce GitOps.

- Secure Config Files – Encrypt sensitive data (keys, tokens).

- Continuous Monitoring – Integrate with Prometheus, Datadog.

- Compliance Alignment – Follow standards (ISO 10218, IEC 61508).

- Fleet-Wide Drift Scans – Use centralized dashboards for multi-robot monitoring.

9. Comparison with Alternatives

| Approach | Suitable For | Pros | Cons |

|---|---|---|---|

| Manual Audits | Small setups | Simple | Error-prone, slow |

| Infrastructure Drift Detection (Terraform, Ansible) | IT + RobotOps hybrid | Mature ecosystem | Not robotics-specific |

| RobotOps Drift Detection | Large robotic fleets | Tailored for ROS, hardware configs | Newer, evolving tools |

Choose RobotOps Drift Detection if:

- You manage robot fleets (not just IT infra).

- You need real-time safety guarantees.

- Compliance and AI-driven adaptation are critical.

10. Conclusion

Configuration Drift Detection is a cornerstone of RobotOps, ensuring robotic systems remain safe, consistent, and compliant throughout their lifecycle.

- Today: Used for monitoring firmware, ROS configs, and robotic fleets.

- Future: AI-driven auto-remediation, predictive drift detection, integration with digital twins.

Next Steps:

- Explore ROS2 Parameter Management

- Learn GitOps for robots: FluxCD or ArgoCD

- Community: ROS Discourse | RobotOps GitHub