Introduction & Overview

Servo motors are critical components in robotics and automation, offering precise control over position, speed, and torque. In the context of RobotOps (Robotics Operations), servo motors are foundational for enabling reliable, efficient, and accurate robotic movements. This tutorial provides a detailed exploration of servo motors, their integration into RobotOps, and practical guidance for implementation.

What is a Servo Motor?

A servo motor is an electromechanical device designed for precise control of angular or linear position. It uses a closed-loop feedback system to maintain accuracy, making it ideal for applications requiring exact movements, such as robotic arms, autonomous vehicles, and industrial automation. Servo motors are typically powered by direct current (DC) or alternating current (AC) and include a motor, feedback sensor, and control circuit.

History or Background

The concept of servo motors traces back to the early 20th century, evolving from simple motor control systems to sophisticated servomechanisms:

- Early 1900s: The term “servo” originates from “servomechanism,” coined to describe systems using feedback for control. Early applications were in naval and aerospace systems for stabilizing equipment like gun turrets.

- 1940s–1950s: Servo motors gained prominence during World War II for radar and autopilot systems, leveraging analog feedback circuits.

- 1960s–1980s: The rise of digital electronics and microcontrollers enabled more precise control, expanding servo motor use in industrial automation and early robotics, such as the General Motors robotic arm in 1961.

- 1990s–Present: Advances in materials, miniaturization, and digital signal processing reduced costs and improved performance, making servo motors ubiquitous in robotics, CNC machines, and consumer electronics like RC vehicles.

Why is it Relevant in RobotOps?

RobotOps integrates DevOps principles with robotics to streamline the development, deployment, and maintenance of robotic systems. Servo motors are vital in RobotOps because:

- Precision Control: Enable robots to perform tasks with high accuracy, critical for automated manufacturing and service robots.

- Integration with CI/CD: Servo motor control can be programmed and updated via continuous integration/continuous deployment (CI/CD) pipelines, ensuring rapid iteration.

- Scalability: Suitable for various robot sizes, from micro-servos in drones to industrial servos in factory automation.

- Reliability: Closed-loop systems ensure consistent performance, aligning with RobotOps’ focus on reliability and monitoring.

Core Concepts & Terminology

Key Terms and Definitions

- Servo Motor: AಸA rotary actuator with a feedback mechanism for precise position control.

- Closed-Loop Control: A system where the motor’s actual position is continuously compared to the desired position, adjusting for errors.

- Pulse Width Modulation (PWM): A control signal method where pulse duration determines the motor’s position or speed.

- Encoder/Potentiometer: Feedback devices that monitor the motor’s position or speed.

- Torque: The rotational force generated by the motor, often measured in kg/cm.

- RobotOps: The application of DevOps practices to robotics, emphasizing automation, monitoring, and continuous improvement.

| Term | Definition | Role in RobotOps |

|---|---|---|

| PWM (Pulse Width Modulation) | A method of controlling servo position by varying signal pulse width. | Used to send control signals to the motor. |

| Feedback Loop | Closed-loop system where sensor data is used to adjust motor output. | Ensures accuracy and stability. |

| Torque | Rotational force generated by the motor. | Determines the strength of robotic arms. |

| Duty Cycle | Percentage of time a signal is ON in a PWM cycle. | Controls angular positioning. |

| Controller (MCU/PLC) | Device that sends signals to the servo. | Acts as the brain in RobotOps pipelines. |

How It Fits into the RobotOps Lifecycle

Servo motors are integral to the RobotOps lifecycle, which includes design, development, testing, deployment, and monitoring:

- Design & Development: Engineers program servo motors to achieve specific movements, integrating with control software.

- Testing: Simulated environments test servo motor performance under various conditions.

- Deployment: Servo motors are deployed in robotic systems, with configurations managed via CI/CD pipelines.

- Monitoring: Real-time feedback from servo motors allows continuous performance monitoring and adjustments.

Architecture & How It Works

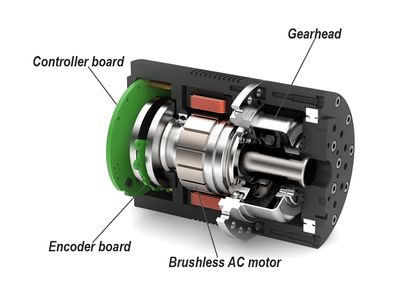

Components

A servo motor consists of several key components working together:

- Motor: DC or AC motor providing rotational energy.

- Gear Train: Reduces speed and increases torque for precise movements.

- Feedback Device: Encoders or potentiometers monitor position or speed.

- Control Circuit: Processes input signals and feedback to drive the motor.

- Output Shaft/Spline: Transfers motion to the robotic component.

Internal Workflow

- Input Signal: A PWM signal specifies the desired position or speed.

- Feedback Comparison: The control circuit compares the feedback signal (actual position) with the input signal.

- Error Correction: The motor adjusts to minimize the difference between actual and desired positions.

- Output Motion: The output shaft moves to the precise position or speed.

Architecture Diagram

Below is a textual description of a servo motor control system architecture (image not possible):

+-------------------+ PWM Signal +--------------------+

| RobotOps Control | ------------------> | Servo Motor Driver |

| System / MCU | | (Control Circuit) |

+-------------------+ +-------------------+

|

v

+-------------------+

| Servo Motor Core |

| (Motor + Gears) |

+-------------------+

|

v

+-------------------+

| Feedback Sensor |

| (Encoder/Pot) |

+-------------------+

|

Feedback <------+

- Controller: Sends PWM signals to the servo motor.

- Control Circuit: Interprets PWM and feedback signals, driving the motor.

- Feedback Device: Provides real-time position/speed data.

- Motor & Gear Train: Executes precise movements.

Integration Points with CI/CD or Cloud Tools

- CI/CD Pipelines: Servo motor control code can be version-controlled, tested, and deployed using tools like Jenkins or GitLab CI/CD.

- Cloud Tools: AWS IoT or Azure IoT Hub can manage servo motor telemetry data for remote monitoring and updates.

- Simulation Tools: ROS (Robot Operating System) integrates with servo motors for testing in virtual environments.

Installation & Getting Started

Basic Setup or Prerequisites

- Hardware: Servo motor (e.g., SG90 for hobbyists, industrial servos for larger applications), microcontroller (e.g., Arduino), power supply (4.8–6V for hobby servos), and connecting wires.

- Software: Arduino IDE, Python, or ROS for programming; servo motor library (e.g., Arduino Servo library).

- Tools: Screwdrivers, soldering kit (optional), and a computer for coding.

Hands-On: Step-by-Step Beginner-Friendly Setup Guide

- Connect the Servo Motor:

- Red wire: Power (VCC, 4.8–6V).

- Black/Brown wire: Ground (GND).

- Yellow/Orange wire: Signal (connected to PWM pin on microcontroller).

- Set Up Arduino:

- Install Arduino IDE from arduino.cc.

- Connect Arduino to your computer via USB.

- Write Control Code:

#include <Servo.h>

Servo myServo;

void setup() {

myServo.attach(9); // Signal pin connected to Arduino pin 9

}

void loop() {

myServo.write(0); // Move to 0 degrees

delay(1000); // Wait 1 second

myServo.write(90); // Move to 90 degrees

delay(1000); // Wait 1 second

}4. Upload Code:

- Connect Arduino to the servo motor.

- Upload the code via Arduino IDE.

5. Test the Setup:

- Power the servo motor and observe its movement between 0 and 90 degrees.

6. Troubleshooting:

- Ensure proper voltage (check servo datasheet).

- Verify connections and PWM signal compatibility.

Real-World Use Cases

RobotOps Scenarios

- Robotic Arm Manipulation:

- Autonomous Vehicles:

- CNC Machines:

- Drones:

Industry-Specific Examples

- Aerospace: Servo motors control ailerons and rudders in aircraft, ensuring precise aerodynamic adjustments.

- Medical Robotics: Surgical robots use servo motors for delicate procedures, such as minimally invasive surgeries.

Benefits & Limitations

Key Advantages

- High Precision: Closed-loop feedback ensures accurate positioning.

- Compact Size: Small servo motors deliver high torque relative to size.

- Programmability: Easily controlled via PWM signals, integrating with microcontrollers.

- Reliability: Robust design suitable for continuous operation in industrial settings.

Common Challenges or Limitations

- Cost: Servo motors are more expensive than standard DC motors.

- Complexity: Requires sophisticated control systems for optimal performance.

- Power Consumption: High torque applications demand significant power.

- Limited Rotation: Standard servos are restricted to 90–180° rotation, though continuous rotation servos exist.

Best Practices & Recommendations

Security Tips

- Secure Connections: Insulate electrical connections to prevent short circuits.

- Firmware Updates: Regularly update control software to patch vulnerabilities.

- Access Control: Restrict access to servo control systems in sensitive applications.

Performance

- Calibration: Regularly calibrate feedback devices for accuracy.

- Power Management: Use a stable power supply matching servo requirements (e.g., 4.8–6V for hobby servos).

- Load Matching: Select servo motors with appropriate torque ratings to avoid stalling.

Maintenance

- Regular Inspection: Check for wear, loose connections, or overheating.

- Lubrication: Ensure gear trains are lubricated to reduce friction.

- Monitoring: Use telemetry data to detect performance degradation.

Compliance Alignment

- Industry Standards: Adhere to standards like ISO 10218 for robotic safety.

- Data Privacy: Ensure telemetry data complies with GDPR or CCPA in cloud-integrated systems.

Automation Ideas

- Automated Testing: Use CI/CD pipelines to test servo motor configurations.

- Remote Monitoring: Implement IoT solutions for real-time performance monitoring.

Comparison with Alternatives

| Feature | Servo Motor | Stepper Motor | DC Motor | Hydraulic Actuator |

|---|---|---|---|---|

| Precision | High (closed-loop feedback) | Moderate (open-loop, step-based) | Low (no feedback) | Moderate (depends on control) |

| Torque | High torque-to-inertia ratio | High at low speeds | Moderate | Very high |

| Cost | Moderate to high | Low to moderate | Low | High |

| Complexity | Complex control systems | Simple control | Simple control | Complex, requires fluid systems |

| Applications | Robotics, CNC, aerospace | 3D printers, CNC | Fans, simple drives | Heavy machinery, presses |

| Maintenance | Moderate (lubrication, calibration) | Low (minimal moving parts) | Low | High (fluid leaks, seals) |

When to Choose Servo Motor

- Choose Servo Motor: For applications requiring high precision, repeatability, and compact size, such as robotic arms, drones, and CNC machines.

- Choose Alternatives:

Conclusion

Servo motors are indispensable in RobotOps, enabling precise, reliable, and programmable motion control. Their integration with CI/CD pipelines, cloud tools, and ROS enhances their role in modern robotics. As robotics advances, servo motors will continue to evolve with improved efficiency, smaller sizes, and smarter control systems.