1. Introduction & Overview

What is CAN Bus?

CAN (Controller Area Network) Bus is a robust, serial communication protocol designed for real-time distributed control. It enables multiple microcontrollers, sensors, and actuators to communicate without a central computer, using a simple two-wire twisted pair system.

In RobotOps (Robot Operations, the DevOps-like methodology for robotics), CAN Bus acts as a nervous system for robots—connecting sensors, motors, controllers, and other components reliably.

History or Background

- 1980s: Developed by Bosch for in-vehicle networks.

- 1991: Standardized as ISO 11898.

- Widely adopted in automotive, robotics, aerospace, and industrial automation.

- Core features: fault tolerance, real-time performance, priority-based arbitration.

Why is it Relevant in RobotOps?

- Robots require low-latency communication between sensors and actuators.

- CAN Bus offers deterministic communication, crucial for autonomous systems.

- In RobotOps pipelines, CAN data can be integrated into CI/CD workflows, monitoring dashboards, and cloud-based control systems.

2. Core Concepts & Terminology

Key Terms and Definitions

| Term | Definition |

|---|---|

| CAN Frame | Data packet with identifier, control, and data fields. |

| Arbitration | Priority-based method for resolving message collisions. |

| Bit Rate | Transmission speed (typically 125 kbps – 1 Mbps). |

| CAN High (CAN_H) & CAN Low (CAN_L) | Differential signaling wires for noise resistance. |

| Node | Any device connected to CAN (sensor, motor controller, ECU). |

| Bus Topology | Physical layout with two-wire twisted pair and terminators. |

How it Fits into the RobotOps Lifecycle

- Development: Simulate CAN traffic in CI/CD.

- Testing: Validate communication latency and error handling.

- Deployment: Integrate CAN-enabled robots into cloud control platforms.

- Monitoring: Collect CAN logs for telemetry, debugging, and predictive maintenance.

3. Architecture & How It Works

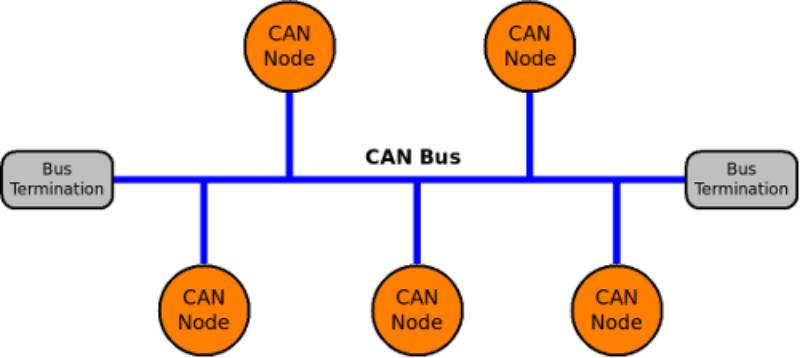

Components

- CAN Controller: Manages data framing and arbitration.

- CAN Transceiver: Converts controller logic signals into differential signals.

- CAN Nodes: Sensors, actuators, motor drivers, ECUs.

- CAN Bus: Twisted pair wiring (CAN_H, CAN_L).

- Termination Resistors: Ensure signal integrity (typically 120Ω at each end).

Internal Workflow

- Message Creation – Node prepares a CAN frame with ID and data.

- Arbitration – If multiple nodes transmit, the lowest ID wins priority.

- Transmission – Bits sent as differential signals.

- Reception – All nodes read messages, decide if relevant.

- Error Handling – Built-in CRC, acknowledgement, and fault detection.

Architecture Diagram (text description)

- Imagine a backbone twisted pair cable (CAN_H & CAN_L).

- Multiple nodes (sensors, motors, controllers) connected in parallel.

- Termination resistors at both ends.

- Messages flow bidirectionally, with priority arbitration ensuring no collisions.

Integration Points with CI/CD or Cloud Tools

- CI/CD: Simulated CAN traffic tests in Jenkins/GitHub Actions pipelines.

- Cloud Monitoring: Stream CAN logs to Grafana/ELK stack for analytics.

- Digital Twin: Integrate CAN signals with cloud-based robot simulators.

- Security: Integrate CAN intrusion detection with cloud security dashboards.

4. Installation & Getting Started

Basic Setup or Prerequisites

- Hardware:

- USB-to-CAN adapter (e.g., PEAK PCAN, CANtact, Arduino with MCP2515).

- Raspberry Pi or Linux machine with SocketCAN support.

- Termination resistors.

- Software:

- Linux with SocketCAN (

can-utils). - Python libraries (

python-can). - Docker/CI pipelines for integration.

- Linux with SocketCAN (

Hands-on Setup (Linux Example)

# Enable CAN interface (using SocketCAN)

sudo ip link set can0 type can bitrate 500000

sudo ip link set up can0

# Send a test CAN frame

cansend can0 123#DEADBEEF

# Receive CAN frames

candump can0

Python example:

import can

bus = can.interface.Bus(channel='can0', bustype='socketcan')

msg = can.Message(arbitration_id=0x123, data=[0xDE, 0xAD, 0xBE, 0xEF], is_extended_id=False)

bus.send(msg)

print("Message sent!")

5. Real-World Use Cases

RobotOps Scenarios

- Autonomous Mobile Robots (AMRs):

CAN bus connects LiDAR sensors, motor controllers, and power systems. - Industrial Arms:

CAN-enabled servo drives ensure synchronized multi-axis control. - Drones & UAVs:

UAVCAN (a CAN-based protocol) used for sensors and motor ESCs. - Medical Robots:

Surgical robots use CAN for precise actuation and real-time feedback.

Industry Examples

- Automotive Robotics: Self-driving cars use CAN for sensor fusion.

- Factory Automation: CAN in robotic conveyor belts and CNC systems.

- Agriculture Robots: Smart tractors and harvesters integrate CAN-based IoT.

6. Benefits & Limitations

Key Advantages

- Real-time, deterministic communication.

- High fault tolerance and error handling.

- Lightweight (no complex protocol stack).

- Scales well for multiple nodes.

Limitations

- Limited bandwidth (1 Mbps typical, CAN-FD extends it).

- Not inherently encrypted (security must be added).

- Physical wiring constraints (30–40m at high speeds).

7. Best Practices & Recommendations

- Security Tips:

- Use CAN gateways with encryption.

- Monitor for abnormal message injection (IDS systems).

- Performance:

- Choose proper bit rates based on bus length.

- Minimize bus load (<70%).

- Maintenance:

- Periodically check terminations.

- Log CAN traffic for diagnostics.

- Compliance & Automation:

- Align with ISO 11898 standards.

- Automate CAN test suites in CI/CD.

8. Comparison with Alternatives

| Protocol | Speed | Reliability | Use Case |

|---|---|---|---|

| CAN Bus | 1 Mbps (CAN-FD: 5–8 Mbps) | High | Robotics, automotive, drones |

| EtherCAT | 100 Mbps | Very High | Industrial robotics (real-time control) |

| Modbus | 115 kbps | Medium | Industrial automation |

| I²C/SPI | 400 kbps – few Mbps | Medium | Short-distance chip communication |

When to choose CAN Bus?

- When reliability > speed (robot sensors, actuators).

- For distributed systems with many nodes.

- For environments with noise (factories, vehicles).

9. Conclusion

- CAN Bus is the backbone of real-time robotic communication.

- In RobotOps, it ensures reliable integration between hardware and DevOps pipelines.

- With tools like SocketCAN and python-can, developers can easily simulate and integrate CAN workflows.

- Future Trends: CAN-FD adoption, cybersecurity enhancements, and tighter cloud-robotics integration.

Next Steps

- Explore SocketCAN docs: Linux CAN Networking

- Join RobotOps & CAN communities:

- UAVCAN Forum

- CAN in Automation (CiA)