Introduction & Overview

The integration of IoT (Internet of Things) hubs into RobotOps (Robotics Operations) is a transformative approach to managing, monitoring, and orchestrating robotic systems at scale. IoT Hub Integration enables seamless communication between robots, cloud platforms, and operational workflows, facilitating real-time data exchange, automation, and analytics in robotics-driven environments. This tutorial provides a detailed guide on implementing IoT Hub Integration within RobotOps, covering its concepts, architecture, setup, use cases, benefits, limitations, best practices, and comparisons with alternatives.

What is IoT Hub Integration?

IoT Hub Integration refers to the process of connecting robotic systems to an IoT hub—a centralized platform that manages device communication, data ingestion, processing, and orchestration. In the context of RobotOps, IoT hubs act as a bridge between robots (equipped with sensors, actuators, and processors) and cloud-based or on-premises systems, enabling real-time monitoring, control, and automation.

History or Background

The concept of IoT hubs emerged with the rise of IoT in the early 2000s, driven by advancements in sensor technology, wireless communication, and cloud computing. Key milestones include:

- Early 2000s: The term “Internet of Things” was coined by Kevin Ashton, focusing on connecting physical objects to the internet via RFID and sensors.

- 2010s: Major cloud providers like Microsoft Azure, AWS, and Google Cloud introduced IoT platforms (e.g., Azure IoT Hub, AWS IoT Core) to manage large-scale device ecosystems.

- 2015–2020: IoT hubs became integral to industrial automation, smart cities, and robotics, with protocols like MQTT and CoAP enabling efficient communication.

- 2020–Present: Integration with RobotOps gained traction as robotics adopted cloud-native architectures, leveraging IoT hubs for fleet management, telemetry, and AI-driven analytics.

Why is it Relevant in RobotOps?

RobotOps, the operational framework for managing robotic systems, relies on seamless data flow, scalability, and automation. IoT Hub Integration is critical because it:

- Enables real-time telemetry for monitoring robot health, performance, and environmental data.

- Supports fleet management by coordinating multiple robots across distributed environments.

- Integrates with CI/CD pipelines for continuous deployment of robot firmware and configurations.

- Facilitates AI and analytics by feeding robot data into machine learning models for predictive maintenance and optimization.

Core Concepts & Terminology

Key Terms and Definitions

| Term | Definition |

|---|---|

| IoT Hub | A cloud-based service that manages bidirectional communication between IoT devices (e.g., robots) and applications. |

| RobotOps | A DevOps-inspired framework for managing robotic systems, including deployment, monitoring, and maintenance. |

| Telemetry | Data collected from robots (e.g., sensor readings, logs) sent to the IoT hub for processing. |

| MQTT/CoAP | Lightweight protocols for IoT communication, optimized for low-bandwidth, high-latency networks. |

| Edge Computing | Processing data closer to the robot to reduce latency and cloud dependency. |

| Device Twin | A digital representation of a robot’s state and configuration in the IoT hub. |

| CI/CD Integration | Continuous integration and deployment pipelines for updating robot software and configurations. |

How It Fits into the RobotOps Lifecycle

IoT Hub Integration spans the RobotOps lifecycle, which includes design, deployment, operation, and maintenance:

- Design: Define robot communication protocols and IoT hub architecture.

- Deployment: Use IoT hubs to push firmware updates and configurations via CI/CD pipelines.

- Operation: Monitor robot telemetry and orchestrate tasks in real time.

- Maintenance: Analyze data for predictive maintenance and optimize performance.

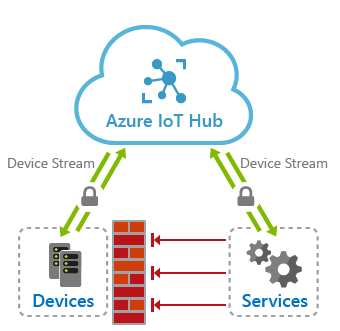

Architecture & How It Works

Components

An IoT Hub Integration architecture in RobotOps comprises:

- Robots/Devices: Equipped with sensors (e.g., temperature, proximity) and actuators (e.g., motors, grippers) to collect and act on data.

- IoT Gateway: Acts as a bridge between robots and the IoT hub, handling protocol translation (e.g., MQTT, Zigbee).

- IoT Hub: Central platform (e.g., Azure IoT Hub, AWS IoT Core) for device management, data routing, and analytics integration.

- Cloud/On-Premises Backend: Stores and processes data, integrates with CI/CD tools, and hosts user applications.

- User Applications: Web/mobile dashboards for monitoring and controlling robots.

Internal Workflow

- Data Collection: Robots collect data via sensors (e.g., environmental conditions, battery levels).

- Data Transmission: Data is sent to the IoT hub via gateways using protocols like MQTT or CoAP.

- Data Processing: The IoT hub routes data to cloud services (e.g., Azure Stream Analytics) or edge devices for real-time processing.

- Action/Control: Commands are sent back to robots (e.g., adjust speed, update firmware) via the IoT hub.

- Monitoring & Analytics: Data is stored in a big data warehouse (e.g., Azure Data Lake) for analysis and visualization.

Architecture Diagram Description

The architecture can be visualized as a layered structure:

- Perception Layer: Robots with sensors/actuators collect raw data.

- Network Layer: IoT gateways transmit data to the IoT hub using MQTT/CoAP over Wi-Fi, 5G, or LoRaWAN.

- Processing Layer: The IoT hub processes data, routes it to cloud services, or delegates to edge devices.

- Application Layer: Dashboards and APIs provide user interaction and integration with CI/CD tools.

Diagram (Text-Based Representation):

[Robots/Sensors] --> [IoT Gateway (MQTT/CoAP)] --> [IoT Hub (Azure/AWS)] --> [Cloud Backend (Analytics, CI/CD)] --> [User Apps/Dashboards]

Integration Points with CI/CD or Cloud Tools

- CI/CD Pipelines: Tools like Jenkins or GitHub Actions integrate with IoT hubs to deploy firmware updates or configurations to robots.

- Cloud Tools: Azure Stream Analytics, AWS Lambda, or Google Cloud Functions process telemetry data for real-time insights.

- APIs: IoT hubs provide REST APIs for integrating with enterprise systems (e.g., ERP, CRM).

Installation & Getting Started

Basic Setup or Prerequisites

- Hardware: Robots with sensors/actuators, IoT gateway (e.g., Raspberry Pi), internet connectivity.

- Software: IoT hub account (e.g., Azure IoT Hub, AWS IoT Core), SDKs (e.g., Azure IoT SDK for Python), and a CI/CD tool (e.g., Jenkins).

- Network: Secure Wi-Fi, 5G, or LoRaWAN for communication.

- Security: TLS/SSL certificates, device authentication keys.

Hands-On: Step-by-Step Beginner-Friendly Setup Guide

This guide uses Azure IoT Hub to integrate a robot with RobotOps.

- Create an Azure IoT Hub:

- Sign in to the Azure portal.

- Create a new IoT Hub resource (e.g., Free tier for testing).

- Note the connection string for device registration.

- Register a Robot:

az iot hub device-identity create --hub-name <your-hub-name> --device-id <robot-id>Retrieve the device connection string.

3. Set Up Robot Software:

- Install Azure IoT SDK for Python:

pip install azure-iot-device- Write a Python script to send telemetry:

from azure.iot.device.aio import IoTHubDeviceClient

import asyncio

import json

async def main():

conn_str = "<device-connection-string>"

client = IoTHubDeviceClient.create_from_connection_string(conn_str)

await client.connect()

telemetry = {"temperature": 25.5, "battery": 80}

await client.send_message(json.dumps(telemetry))

print("Telemetry sent")

await client.disconnect()

if __name__ == "__main__":

asyncio.run(main())4. Configure CI/CD Pipeline:

- Set up a GitHub repository with robot firmware code.

- Create a GitHub Action to deploy updates:

name: Deploy Firmware

on: [push]

jobs:

deploy:

runs-on: ubuntu-latest

steps:

- uses: actions/checkout@v3

- name: Deploy to IoT Hub

run: |

az iot hub device-identity update --hub-name <your-hub-name> --device-id <robot-id> --set properties.desired.firmwareVersion=1.05. Monitor Telemetry:

- Use Azure IoT Explorer or a custom dashboard to view telemetry data.

Real-World Use Cases

- Warehouse Automation:

- Scenario: Autonomous mobile robots (AMRs) in a warehouse use IoT Hub Integration to coordinate picking and packing tasks.

- Implementation: AMRs send telemetry (e.g., location, battery status) to Azure IoT Hub, which routes data to a warehouse management system (WMS) for task allocation.

- Industry: Logistics.

- Precision Agriculture:

- Scenario: IoT-enabled drones monitor soil moisture and crop health, sending data to an IoT hub for analysis.

- Implementation: Drones use MQTT to send data to AWS IoT Core, which triggers irrigation commands based on AI analytics.

- Industry: Agriculture.

- Healthcare Robotics:

- Scenario: Surgical robots stream telemetry to an IoT hub for real-time monitoring by surgeons.

- Implementation: Robots use CoAP to send data to Google Cloud IoT Core, integrated with a hospital’s EHR system.

- Industry: Healthcare.

- Smart Manufacturing:

- Scenario: Industrial robots on a factory floor report performance metrics to predict maintenance needs.

- Implementation: Robots connect to Azure IoT Hub, which feeds data to Azure Machine Learning for predictive maintenance.

- Industry: Manufacturing.

Benefits & Limitations

Key Advantages

- Scalability: IoT hubs can manage thousands of robots, supporting large-scale RobotOps.

- Real-Time Insights: Enables immediate decision-making with low-latency data processing.

- Automation: Integrates with CI/CD for seamless firmware updates and task orchestration.

- Security: Offers robust encryption and authentication mechanisms.

Common Challenges or Limitations

- Complexity: Integrating diverse robots and protocols can be challenging.

- Cost: Cloud-based IoT hubs may incur significant costs for large-scale deployments.

- Latency: Cloud processing can introduce delays compared to edge computing.

- Interoperability: Different vendors’ protocols may require additional gateways.

Best Practices & Recommendations

Security Tips

- Use TLS/SSL for end-to-end encryption.

- Implement device authentication with X.509 certificates or SAS tokens.

- Regularly update firmware to patch vulnerabilities.

Performance

- Leverage edge computing for low-latency processing in time-sensitive applications.

- Optimize data transmission with lightweight protocols like MQTT or CoAP.

Maintenance

- Monitor device health using IoT hub telemetry.

- Automate firmware updates via CI/CD pipelines.

Compliance Alignment

- Adhere to standards like GDPR for data privacy and ISO/IEC 27001 for security.

- Implement audit logs for compliance tracking.

Automation Ideas

- Use IoT hub rules to trigger automated actions (e.g., alerts for low battery).

- Integrate with serverless functions (e.g., Azure Functions) for event-driven automation.

Comparison with Alternatives

| Feature/Aspect | IoT Hub (e.g., Azure IoT Hub) | MQTT Broker | Edge-Only Solutions |

|---|---|---|---|

| Scalability | High (thousands of devices) | Moderate | Low (device-limited) |

| Cloud Integration | Seamless (AWS, Azure, GCP) | Limited | None |

| Security | Robust (TLS, device twins) | Basic | Device-dependent |

| Latency | Moderate (cloud-based) | Low | Very low (local) |

| Cost | High (subscription-based) | Low | Moderate |

When to Choose IoT Hub Integration

- Choose IoT Hub: For large-scale, cloud-integrated RobotOps with complex analytics and CI/CD needs.

- Choose MQTT Broker: For lightweight, low-latency communication in constrained environments.

- Choose Edge-Only: For ultra-low-latency applications with no cloud dependency.

Conclusion

IoT Hub Integration is a cornerstone of modern RobotOps, enabling scalable, secure, and automated management of robotic systems. By connecting robots to cloud platforms, it facilitates real-time monitoring, predictive maintenance, and seamless CI/CD integration. While challenges like complexity and cost exist, best practices such as edge computing and robust security measures can mitigate them. As robotics and IoT continue to evolve, future trends may include AI-driven automation and 5G-enabled low-latency communication.

Next Steps

- Explore official documentation: Azure IoT Hub, AWS IoT Core.

- Join communities: IoT Developer Forum, RobotOps Slack.

- Experiment with a small-scale IoT hub setup to understand its impact on RobotOps.