Introduction & Overview

What is a System on Chip (SoC)?

A System on Chip (SoC) is an integrated circuit that consolidates multiple components of a computer or electronic system into a single chip. These components typically include a central processing unit (CPU), graphics processing unit (GPU), memory, input/output (I/O) ports, and peripheral interfaces, such as UART, SPI, or I2C. By integrating these elements, SoCs achieve compact size, reduced power consumption, and enhanced performance compared to traditional multi-chip architectures. SoCs are foundational to modern electronics, powering devices like smartphones, IoT gadgets, and robotic systems.

History or Background

The concept of SoC emerged in the late 20th century as semiconductor technology advanced, enabling greater transistor density on a single chip. Key milestones include:

- 1980s–1990s: Early integrated circuits combined basic components, but true SoCs began with the integration of microprocessors and peripherals for embedded systems.

- Early 2000s: The rise of mobile devices, such as the iPhone (featuring the A4 SoC in 2010), popularized SoCs by integrating CPU, GPU, and modems for compact, power-efficient designs.

- 2010s: SoCs evolved with multicore processors, advanced GPUs, and specialized units like Digital Signal Processors (DSPs) and Neural Processing Units (NPUs), driven by demands from IoT, AI, and robotics.

- 2020s: Modern SoCs leverage advanced process nodes (e.g., 3nm by TSMC) and heterogeneous architectures (e.g., ARM’s big.LITTLE) for optimized performance and energy efficiency, critical for robotics and autonomous systems.

This evolution reflects the trend toward tighter integration, driven by Moore’s Law and the need for compact, efficient systems in applications like RobotOps.

Why is it Relevant in RobotOps?

RobotOps, or Robot Operations, is the practice of integrating DevOps principles into the development, deployment, and management of robotic systems. SoCs are pivotal in RobotOps because they:

- Enable Compact Designs: Robots require small, lightweight hardware for mobility and efficiency, which SoCs provide by integrating multiple functions.

- Support Real-Time Processing: SoCs with DSPs and NPUs handle sensor data, AI inference, and control tasks in real time, critical for autonomous robots.

- Facilitate Scalability: Programmable SoCs (e.g., Xilinx Zynq) allow RobotOps teams to customize hardware and software for specific robotic tasks.

- Integrate with CI/CD: SoCs support over-the-air (OTA) updates and cloud integration, aligning with RobotOps’ focus on continuous deployment and monitoring.

In RobotOps, SoCs bridge hardware and software, enabling agile development and deployment of robotic systems in industries like manufacturing, logistics, and healthcare.

Core Concepts & Terminology

Key Terms and Definitions

| Term | Definition |

|---|---|

| SoC | System on Chip, an integrated circuit combining CPU, GPU, memory, and peripherals on a single chip. |

| CPU | Central Processing Unit, the core processor handling general-purpose computing tasks. |

| GPU | Graphics Processing Unit, specialized for rendering visuals and parallel processing tasks like AI. |

| DSP | Digital Signal Processor, optimized for signal processing tasks like audio or sensor data analysis. |

| NPU | Neural Processing Unit, dedicated hardware for AI and machine learning tasks. |

| NoC | Network on Chip, an interconnection architecture for efficient communication between SoC components. |

| IP Core | Reusable design blocks (e.g., processor cores or peripherals) integrated into SoCs. |

| FPGA | Field-Programmable Gate Array, a programmable hardware platform often used in SoCs for flexibility. |

| RTL | Register Transfer Level, a design abstraction for modeling digital circuits in hardware description languages (HDL). |

How it Fits into the RobotOps Lifecycle

In RobotOps, SoCs are integral across the lifecycle of robotic system development and operation:

- Design Phase: Engineers select SoCs based on performance, power, and peripheral requirements, often using tools like MATLAB/Simulink for modeling.

- Development Phase: Hardware-software co-design leverages SoC programmability to implement control algorithms and sensor processing.

- Testing Phase: Functional verification, using tools like Synopsys VCS, ensures the SoC meets robotic application needs.

- Deployment Phase: SoCs enable OTA updates and cloud integration for continuous deployment, aligning with CI/CD pipelines.

- Monitoring Phase: SoCs with built-in diagnostics support real-time telemetry and performance monitoring in robotic systems.

Architecture & How It Works

Components and Internal Workflow

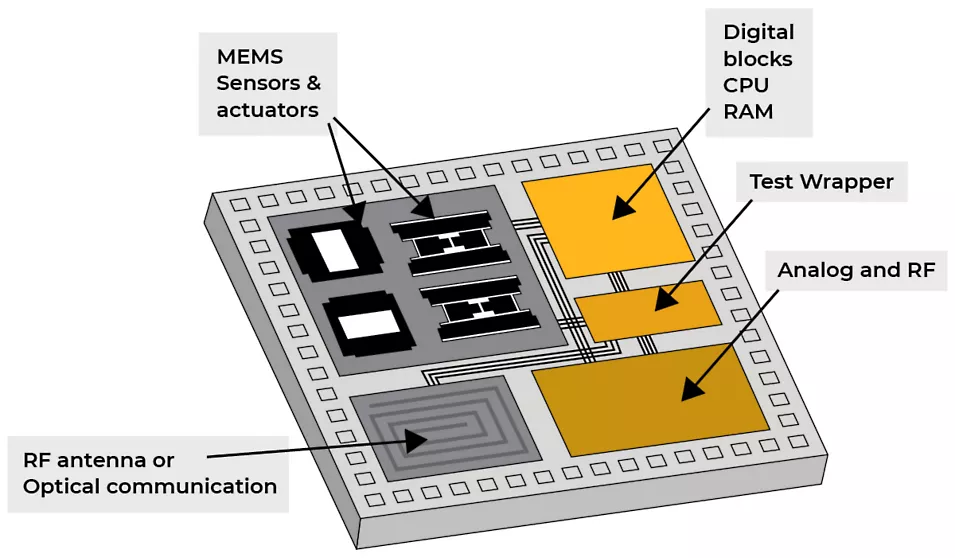

An SoC typically includes:

- Processor Cores: Microcontrollers, microprocessors, or DSPs (e.g., ARM Cortex-A or Cortex-M) handle computation and control tasks.

- Memory: On-chip RAM, ROM, or flash for data storage, often supplemented by off-chip DDR memory for high-bandwidth tasks.

- Peripherals: Interfaces like UART, SPI, I2C, USB, and GPIO for communication with sensors, actuators, and external devices.

- GPU/NPU: For rendering visuals or accelerating AI tasks, such as object detection in robotic vision.

- Interconnects: Network-on-Chip (NoC) or buses (e.g., AXI4) for efficient data transfer between components.

- Power Management: Voltage regulators and clock sources to optimize energy use.

- Signal Processing Units: ADCs/DACs for analog-to-digital conversion in sensor processing.

The workflow involves the CPU executing instructions, coordinating with peripherals for I/O, and leveraging specialized units (GPU/NPU) for compute-intensive tasks. NoC ensures low-latency communication, critical for real-time robotic control.

Architecture Diagram

Below is a textual description of a typical SoC architecture for RobotOps, as images cannot be included:

┌─────────────────────────────┐

│ Cloud/CI-CD Tools │

│ (K8s, Jenkins, GitHub) │

└──────────────┬──────────────┘

│ OTA Updates

┌────────────────────┴────────────────────┐

│ SoC │

┌────────┼────────────────────────────────────────┼─────────┐

│ CPU │ GPU/NPU │ DSP │ Memory │ I/O Interfaces │ Security│

│ Control│ AI/ML │ RT │ Cache │ CAN, I²C, SPI │ TPM │

└────────┴─────────┴─────┴────────┴────────────────┴─────────┘

│

┌──────┼───────┐

Sensors │ Actuators

(Camera, Lidar) (Motors, Arms, Wheels)

- CPU: Executes control algorithms and coordinates tasks.

- GPU/NPU: Processes sensor data (e.g., camera feeds) or runs AI models.

- Memory: Stores firmware, data, and temporary computations.

- NoC: Routes data between components with low latency.

- Peripherals: Interface with sensors (e.g., LIDAR) and actuators.

- Power Management: Optimizes energy use for battery-powered robots.

- External Interfaces: Enable cloud connectivity for OTA updates.

Integration Points with CI/CD or Cloud Tools

SoCs integrate with RobotOps CI/CD pipelines and cloud tools via:

- OTA Updates: SoCs with flash memory support firmware updates through cloud platforms like AWS IoT or Azure IoT Hub.

- Simulation Tools: MATLAB/Simulink or Synopsys VCS simulate SoC behavior, integrating with CI/CD for automated testing.

- Monitoring: SoCs with telemetry capabilities send performance data to cloud dashboards (e.g., Grafana) for real-time monitoring.

- DevOps Tools: Jenkins automates regression testing of SoC firmware, reducing manual effort by up to 50%.

Installation & Getting Started

Basic Setup or Prerequisites

To work with SoCs in RobotOps, you need:

- Hardware: A development board with an SoC (e.g., Xilinx Zynq-7000, Raspberry Pi with Broadcom SoC).

- Software:

- EDA tools (e.g., Synopsys VCS, Cadence Incisive).

- HDL tools (e.g., Vivado for Xilinx SoCs).

- Development environment (e.g., Linux with GCC, Python).

- Robot Operating System (ROS) for robotic control.

- Knowledge: Basics of RTL, embedded systems, and RobotOps principles.

- Connectivity: Wi-Fi/Ethernet for cloud integration.

Hands-On: Step-by-Step Beginner-Friendly Setup Guide

This guide sets up a Xilinx Zynq-7000 SoC for a robotic application using ROS.

- Set Up Development Environment:

- Install Ubuntu 20.04 or later on your PC.

- Install Vivado Design Suite:

sudo apt install xilinx-vivado. - Install ROS Noetic:

sudo sh -c 'echo "deb http://packages.ros.org/ros/ubuntu focal main" > /etc/apt/sources.list.d/ros-latest.list'

sudo apt update

sudo apt install ros-noetic-desktop-full2. Configure Zynq-7000 Board:

- Connect the Zynq-7000 board (e.g., ZedBoard) to your PC via USB.

- Power on the board and ensure it’s detected:

lsusb.

3. Create a Simple SoC Design:

- Open Vivado and create a new project targeting the Zynq-7000.

- Add an ARM Cortex-A9 core and GPIO peripherals using the IP Integrator.

- Generate a bitstream:

vivado -mode batch -source generate_bitstream.tcl4. Program the SoC:

- Load the bitstream onto the FPGA:

vivado -mode tcl -source program_fpga.tcl. - Flash a Linux image with ROS support onto the board’s SD card.

5. Run a ROS Node:

- SSH into the Zynq board:

ssh user@zynq-board-ip. - Start a ROS node to control a sensor:

source /opt/ros/noetic/setup.bash

rosrun my_package sensor_node

6. Integrate with CI/CD:

- Set up a Jenkins pipeline to automate bitstream generation and testing:

pipeline {

agent any

stages {

stage('Build') {

steps {

sh 'vivado -mode batch -source build.tcl'

}

}

stage('Test') {

steps {

sh 'rosrun my_package test_node'

}

}

}

}This setup provides a foundation for developing RobotOps applications on an SoC.

Real-World Use Cases

RobotOps Scenarios

- Autonomous Warehouse Robot:

- Application: An SoC (e.g., NVIDIA Jetson Nano) powers a warehouse robot for navigation and inventory management.

- Details: The SoC’s GPU processes LIDAR and camera data for obstacle avoidance, while the CPU runs ROS nodes for path planning. Cloud integration via Wi-Fi enables real-time inventory updates.

- Industry: Logistics.

- Medical Robotic Assistant:

- Application: An SoC (e.g., Qualcomm Snapdragon) drives a robotic arm for surgical assistance.

- Details: The NPU accelerates AI for tissue recognition, and peripherals interface with sensors for precise movements. OTA updates ensure compliance with medical standards.

- Industry: Healthcare.

- Smart Home Robot:

- Application: An SoC (e.g., ESP32) powers a home cleaning robot.

- Details: The SoC’s Bluetooth/Wi-Fi modules connect to a smart home hub, while the microcontroller processes sensor data for navigation. Low power consumption extends battery life.

- Industry: Consumer Electronics.

- Industrial Inspection Drone:

- Application: An SoC (e.g., AMD Zynq UltraScale+) controls a drone for factory inspections.

- Details: The FPGA accelerates image processing, and the ARM core runs control algorithms. Cloud connectivity enables real-time data streaming to monitoring dashboards.

- Industry: Manufacturing.

Benefits & Limitations

Key Advantages

- Compact Size: Integrates multiple components, reducing robot size and weight.

- Power Efficiency: Optimized interconnects and power management lower energy consumption, ideal for battery-powered robots.

- High Performance: Heterogeneous cores (CPU, GPU, NPU) enable real-time processing for AI and control tasks.

- Customizability: Programmable SoCs (e.g., FPGAs) allow tailored solutions for specific robotic applications.

- Faster Time to Market: Reusable IP cores reduce development time by up to 50%.

Common Challenges or Limitations

| Challenge | Description |

|---|---|

| Single Point of Failure | Failure of one component affects the entire SoC, limiting upgrades. |

| Design Complexity | Designing custom SoCs takes 6–12 months and requires specialized tools. |

| Limited Flexibility | SoCs are optimized for specific tasks, reducing adaptability for other uses. |

| Analog Performance | Single-process technology limits analog performance, making SoCs better for digital tasks. |

Best Practices & Recommendations

Security Tips

- Secure Boot: Use SoC features like ARM TrustZone to ensure only verified firmware runs.

- Encryption: Implement hardware-based encryption for data transmitted to cloud platforms.

- Regular Updates: Leverage OTA capabilities to patch vulnerabilities promptly.

Performance

- Optimize NoC: Use destination-specific routing to reduce latency in real-time tasks.

- Power Management: Configure dynamic voltage scaling to balance performance and energy use.

- Parallel Processing: Exploit GPU/NPU parallelism for compute-intensive tasks like vision processing.

Maintenance

- Diagnostics: Use SoC telemetry for proactive monitoring of robot health.

- Version Control: Integrate with Git for tracking firmware changes in CI/CD pipelines.

- Regression Testing: Automate tests with tools like Jenkins to ensure firmware reliability.

Compliance Alignment

- Industry Standards: Ensure SoCs meet standards like ISO 26262 for automotive or IEC 60601 for medical devices.

- Data Privacy: Comply with GDPR or HIPAA for robots handling sensitive data.

Automation Ideas

- CI/CD Integration: Automate SoC firmware builds and tests using Jenkins or GitLab CI.

- Cloud Monitoring: Use AWS IoT or Azure IoT Hub for real-time telemetry and alerts.

Comparison with Alternatives

| Feature | SoC | Single Board Computer (SBC) | Multi-Chip Module (MCM) |

|---|---|---|---|

| Integration | All components on one chip | Components on a board | Multiple chips in one package |

| Size | Very compact | Larger than SoC | Compact but larger than SoC |

| Power Efficiency | High (short interconnects) | Moderate | Moderate |

| Customizability | High with FPGAs | Limited | Moderate |

| Cost | High for custom designs | Low for off-the-shelf | Moderate |

| Use Case | Robotics, IoT, smartphones | Prototyping, hobbyist projects | High-performance computing |

When to Choose SoC

- Choose SoC: For compact, power-efficient, high-performance robotic systems requiring real-time processing and cloud integration (e.g., autonomous drones, medical robots).

- Choose SBC: For prototyping or applications where modularity and low cost are priorities (e.g., Raspberry Pi for educational robots).

- Choose MCM: For applications needing high performance but not extreme integration (e.g., server-grade systems).

Conclusion

SoCs are the backbone of modern robotic systems in RobotOps, enabling compact, efficient, and high-performance solutions. Their ability to integrate CPUs, GPUs, NPUs, and peripherals on a single chip supports real-time processing and cloud connectivity, aligning with RobotOps’ CI/CD and monitoring practices. Despite challenges like design complexity and limited flexibility, SoCs remain critical for advancing robotics in industries like logistics, healthcare, and manufacturing.

Future Trends

- Advanced Process Nodes: 3nm and beyond will enhance performance and efficiency.

- Heterogeneous Architectures: Continued adoption of big.LITTLE and chiplet designs for optimized workloads.

- AI Integration: NPUs will become standard for AI-driven robotics, reducing latency in tasks like object detection.

Next Steps

- Explore SoC development with tools like Vivado or Synopsys VCS.

- Experiment with ROS on SoC-based boards like Xilinx Zynq or NVIDIA Jetson.

- Join communities like the ROS Discourse or ARM Developer forums for collaboration.