1. Introduction & Overview

The rapid adoption of robotics in manufacturing, logistics, healthcare, and autonomous vehicles has introduced new challenges:

- How do we monitor, control, and update hundreds or thousands of robots simultaneously?

- How do we ensure real-time coordination and reliability across diverse environments?

This is where Robot Fleet Management (RFM) comes into play. It acts as the “control tower” for multiple robots, ensuring that they work together efficiently, securely, and reliably within an organization.

What is Robot Fleet Management?

Robot Fleet Management is the practice of deploying, monitoring, updating, and optimizing large groups of robots (fleets) from a centralized platform.

- It ensures task allocation, status tracking, communication, and updates are automated.

- Think of it as Kubernetes for Robots: while Kubernetes orchestrates containers, RFM orchestrates robots.

History & Background

- Early robotics (1990s–2000s): Robots were standalone units managed individually.

- 2010s: With IoT and AI, multi-robot coordination became possible (e.g., warehouse robots by Amazon Robotics).

- Now (2025): Fleet management is critical in RobotOps (Robotics Operations), where DevOps principles are applied to robots for scalability, automation, and resilience.

Why is it Relevant in RobotOps?

RobotOps focuses on:

- Automation: CI/CD pipelines for robotic software.

- Scalability: Handling fleets from 10 to 10,000 robots.

- Resilience: Monitoring failures and ensuring uptime.

- Compliance: Data security, audit logs, and industry standards.

Without fleet management, organizations cannot scale robotic deployments effectively.

2. Core Concepts & Terminology

Here are the key terms you’ll encounter:

| Term | Definition | Example |

|---|---|---|

| Robot Fleet | A group of robots managed collectively | 500 warehouse robots |

| Fleet Manager | Central controller/platform for fleet orchestration | AWS RoboMaker Fleet Management |

| Mission Control | Task assignment and scheduling system | Assigning delivery routes |

| Teleoperation | Remote human intervention in robot control | Operator controls robot via dashboard |

| Digital Twin | Virtual representation of robot and environment | Simulating traffic for delivery drones |

| OTA (Over-The-Air) Updates | Remotely updating robot software | Pushing security patch to all robots |

Fit into the RobotOps Lifecycle

Robot Fleet Management aligns with RobotOps stages:

- Development → Build robot software.

- Testing → Validate in simulation.

- Deployment → Deploy to fleet via CI/CD.

- Monitoring → Telemetry and performance data.

- Optimization → Improve algorithms, task scheduling.

3. Architecture & How It Works

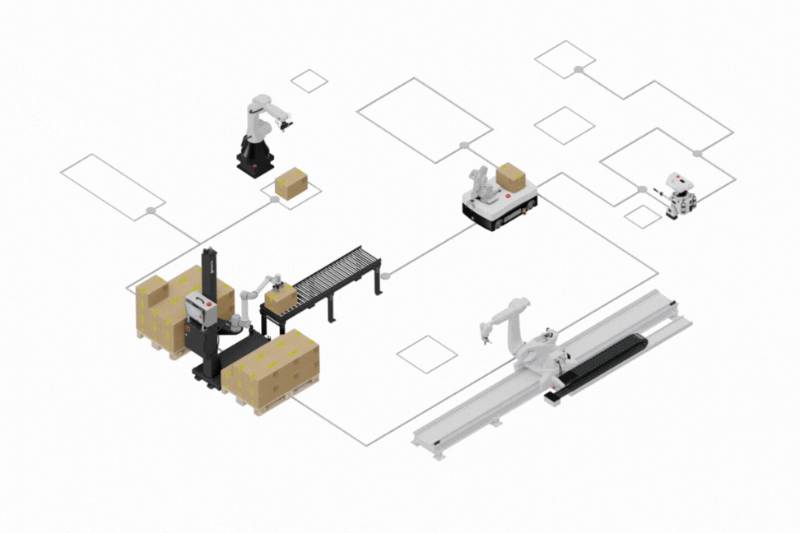

Robot Fleet Management systems follow a hub-and-spoke architecture:

Core Components

- Central Fleet Manager (Cloud or On-Prem): The brain controlling missions, updates, and monitoring.

- Robots (Edge Devices): Execute tasks, send telemetry, receive commands.

- Communication Layer: Secure MQTT, ROS2 DDS, or gRPC channels.

- Operator Dashboard: Web or mobile interface for monitoring & teleoperation.

- CI/CD Integration: Pipelines to push updates to robots.

Internal Workflow

- Operator assigns a mission via dashboard.

- Fleet manager schedules and distributes tasks.

- Robots execute and send telemetry (status, health).

- Monitoring system alerts if failure detected.

- CI/CD pipelines push OTA updates to fleet.

Architecture Diagram (Described)

[ DevOps CI/CD ] ---> [ Fleet Manager (Cloud) ]

|

-----------------------------------------

| | | |

[Robot A] [Robot B] [Robot C] [Robot N]

|

Telemetry + Task Execution

Integration Points with CI/CD & Cloud Tools

- GitHub Actions/Jenkins: Automate robot software builds.

- AWS RoboMaker / Azure Robotics Services: Cloud-hosted fleet management.

- Kubernetes / Edge Computing: Run microservices at the edge.

- Grafana/Prometheus: Robot health monitoring.

4. Installation & Getting Started

Prerequisites

- ROS2 (Robot Operating System 2) installed.

- Docker & Kubernetes (for scaling).

- Cloud account (AWS, Azure, or GCP).

- Secure communication (TLS, VPN).

Basic Setup Example: ROS2 Fleet Management

Step 1 – Install ROS2

sudo apt update && sudo apt install ros-humble-desktop

Step 2 – Launch Fleet Management Package

ros2 launch fleet_management_system fleet_manager.launch.py

Step 3 – Register Robots

ros2 service call /register_robot fleet_msgs/RegisterRobot "{id: 'robot1', type: 'AMR'}"

Step 4 – Assign Mission

ros2 service call /assign_mission fleet_msgs/AssignMission "{robot_id: 'robot1', task: 'deliver_package'}"

Step 5 – Monitor Fleet

- Open dashboard: http://localhost:8080/dashboard

- View live status of all robots.

This is the hello-world setup for RFM in a small lab.

5. Real-World Use Cases

📦 Logistics & Warehousing

- Amazon, DHL, and Alibaba manage thousands of robots moving goods.

- Fleet management assigns picking routes and monitors robot health.

🚗 Autonomous Vehicles

- Robotaxi fleets (e.g., Waymo, Cruise) rely on centralized fleet managers.

- Ensures safety, OTA updates, and real-time rerouting.

🏥 Healthcare Robotics

- Hospital delivery robots (medicines, supplies).

- Fleet management ensures non-collision paths and timely delivery.

🌾 Agriculture Drones

- Drones spraying crops in large farms.

- Centralized manager schedules coverage zones and battery swaps.

6. Benefits & Limitations

✅ Key Advantages

- Centralized monitoring & control.

- OTA updates across large fleets.

- Optimized task scheduling & routing.

- Better security & compliance.

- Reduced downtime with proactive alerts.

⚠️ Common Challenges

- High network dependency (latency issues).

- Scalability limits without cloud-native design.

- Complex security management (TLS, RBAC).

- Difficulties in interoperability (different robot vendors).

7. Best Practices & Recommendations

- Security First:

- Use TLS & VPNs for robot-cloud communication.

- Role-based access control for operators.

- Performance Optimization:

- Deploy edge computing to reduce latency.

- Use message queues (MQTT, Kafka) for event handling.

- Compliance & Maintenance:

- Keep audit logs for safety regulations.

- Automate OTA patches regularly.

- Automation Ideas:

- Integrate CI/CD for fast updates.

- Self-healing workflows (robots auto-switch to backup mission).

8. Comparison with Alternatives

| Approach | Robot Fleet Management | Manual Control | Ad-hoc Scripting |

|---|---|---|---|

| Scalability | Excellent (1000s robots) | Poor | Moderate |

| OTA Updates | Yes | No | Limited |

| Monitoring | Centralized dashboards | Per-robot | Logs only |

| Security | TLS, RBAC | Weak | Custom |

| Best For | Large enterprises, multi-robot ops | Labs | Small teams |

👉 Choose Robot Fleet Management if you have >10 robots, require centralized monitoring, or need cloud integration.

9. Conclusion

Robot Fleet Management is the backbone of RobotOps – enabling scalable, secure, and efficient robotic operations.

- It transforms robots from isolated units into coordinated fleets.

- With integration into CI/CD, cloud platforms, and monitoring tools, it brings DevOps-like agility to robotics.

Future Trends

- AI-driven task allocation (self-optimizing fleets).

- 5G & edge computing for ultra-low latency.

- Interoperability standards for multi-vendor fleets.

Next Steps

- Explore AWS RoboMaker Fleet Management or Open-RMF (Open Robotics Fleet Management Framework).

- Join robotics communities like ROS Discourse and Open Robotics Slack.

- Start small (2–5 robots) and scale with cloud integration.

Official References:

- Open-RMF Documentation

- AWS RoboMaker Fleet Management

- ROS2 Fleet Management Packages