Introduction & Overview

Real-Time Operating Systems (RTOS) are specialized operating systems designed to manage tasks with strict timing constraints, making them critical for applications where timing is paramount, such as robotics, automotive systems, and industrial automation. In the context of RobotOps (Robotics Operations), RTOS plays a pivotal role in ensuring that robotic systems operate reliably, predictably, and efficiently. This tutorial provides an in-depth exploration of RTOS, its architecture, integration into RobotOps, and practical guidance for implementation, tailored for technical readers.

What is a Real-Time Operating System (RTOS)?

An RTOS is an operating system that processes data and events under strictly defined time constraints, ensuring deterministic and predictable responses. Unlike general-purpose operating systems (GPOS) like Windows or Linux, which prioritize multitasking and user interaction, an RTOS focuses on executing critical tasks within precise deadlines. RTOS is categorized into:

- Hard Real-Time: Missing a deadline results in system failure (e.g., robotic arm control in manufacturing).

- Soft Real-Time: Missing a deadline reduces performance but doesn’t cause failure (e.g., multimedia streaming in robots).

- Firm Real-Time: Missing deadlines has minor consequences but is undesirable (e.g., sensor data processing).

History or Background

The concept of real-time computing emerged in the 1960s with early systems developed at Cambridge University, designed to handle multiple processes within strict time limits. Over the decades, RTOS evolved with advancements in hardware and the growing demand for reliable real-time performance in industries like aerospace, defense, and robotics. Key milestones include:

- 1960s: Cambridge University develops one of the first RTOS for concurrent process execution.

- 1980s: Commercial RTOS like VxWorks and QNX emerged, targeting embedded systems.

- 2000s: Open-source RTOS like FreeRTOS gained popularity due to their flexibility and community support.

- 2010s–Present: Integration with IoT, cloud, and advanced robotics, with systems like Zephyr and ROS 2 addressing modern needs.

Why is it Relevant in RobotOps?

RobotOps, the practice of managing the lifecycle of robotic systems through development, deployment, and maintenance, relies on RTOS for:

- Deterministic Performance: Ensures robots respond to sensor inputs or control commands within milliseconds.

- Resource Efficiency: Manages limited hardware resources in embedded robotic systems.

- Scalability: Supports complex, multi-threaded applications in modern robotics, such as autonomous drones or industrial robots.

- Reliability: Critical for safety-critical applications like medical robots or autonomous vehicles.

Core Concepts & Terminology

Key Terms and Definitions

- Task: A unit of execution (or thread) with specific timing constraints, managed by the RTOS scheduler.

- Scheduler: The RTOS component that determines which task runs at a given time, using algorithms like priority-based or earliest deadline first (EDF).

- Task Control Block (TCB): A data structure storing task information (e.g., stack pointer, priority).

- Context Switching: The process of saving and restoring task states to switch CPU control between tasks.

- Interrupt Latency: The time between an interrupt occurrence and the start of its handler.

- Determinism: The guarantee that tasks complete within a specified timeframe.

- Kernel: The core of the RTOS, providing services like task management, memory allocation, and inter-task communication.

| Term | Definition | Example in RobotOps |

|---|---|---|

| Determinism | Guarantee that tasks complete within a known time limit | Emergency stop in robotic arms |

| Task/Thread | Smallest schedulable unit of execution | Motor control loop |

| Scheduler | Algorithm deciding which task runs at a given time | Priority scheduling for obstacle detection |

| Latency | Time taken between an event and system response | Sensor → actuator reaction time |

| ISR (Interrupt Service Routine) | Code executed immediately when an interrupt occurs | Emergency brake trigger |

| Context Switch | Switching CPU control between tasks | From camera processing → path planning |

| Hard RTOS | Strict timing guarantees (failure = catastrophic) | Aerospace drones |

| Soft RTOS | Timing important but not fatal if delayed | Service robots |

| RTOS Kernel | Core part managing scheduling, synchronization, and IPC | FreeRTOS kernel |

How It Fits into the RobotOps Lifecycle

In RobotOps, RTOS is integral across the development, deployment, and maintenance phases:

- Development: RTOS provides a framework for writing modular, time-sensitive code for robotic tasks (e.g., sensor processing, motor control).

- Deployment: Ensures predictable execution on robotic hardware, critical for real-time operations like navigation or manipulation.

- Maintenance: Facilitates debugging and updates through modular architectures, reducing downtime in robotic systems.

- Monitoring: RTOS logs and trace tools (e.g., Percepio Tracealyzer) help monitor task performance and timing.

Architecture & How It Works

Components

An RTOS typically consists of:

- Kernel: Manages tasks, memory, and interrupts, acting as an abstraction layer between hardware and applications.

- Scheduler: Prioritizes and switches tasks using algorithms like:

- Task Management: Handles task creation, deletion, and state transitions (running, ready, waiting, inactive).

- Inter-Task Communication: Mechanisms like semaphores, mutexes, and message queues ensure synchronized data exchange.

- Memory Management: Allocates memory statically or dynamically, avoiding fragmentation in embedded systems.

- Interrupt Handling: Manages hardware interrupts with minimal latency.

Internal Workflow

- Task Creation: The RTOS creates tasks with defined priorities and allocates resources (e.g., stack, TCB).

- Scheduling: The scheduler selects the highest-priority task to run based on the chosen algorithm.

- Context Switching: The RTOS saves the current task’s context (registers, stack pointer) and loads the next task’s context.

- Interrupt Handling: Hardware interrupts trigger the RTOS to execute interrupt service routines (ISRs) while preserving task states.

- Inter-Task Communication: Tasks exchange data using RTOS-provided mechanisms to avoid conflicts.

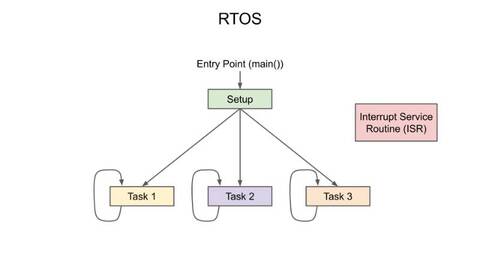

Architecture Diagram

Below is a textual description of an RTOS architecture diagram, as images cannot be generated directly:

- Layers:

- Application Layer: Contains user-defined tasks (e.g., sensor reading, motor control).

- RTOS Kernel: Includes scheduler, task manager, memory manager, and communication modules.

- Hardware Abstraction Layer (HAL): Interfaces with the hardware (e.g., CPU, sensors, actuators).

- Components:

- Tasks: Represented as blocks, each with a TCB and stack.

- Scheduler: A central block connected to tasks, determining execution order.

- Inter-Task Communication: Arrows showing data flow via semaphores or message queues.

- Interrupt Handlers: Connected to the hardware layer, feeding into the scheduler.

- Flow:

- Hardware events (interrupts) trigger the kernel, which schedules tasks.

- Tasks communicate through the kernel, ensuring synchronized execution.

+--------------------------------------------------------+

| RobotOps Cloud / CI/CD Pipeline |

| - Build Automation - Test Framework - Monitoring |

+--------------------------------------------------------+

| |

v v

+--------------------------------------------------------+

| RTOS Architecture (Robot Controller) |

| |

| +-------------------+ +-------------------------+ |

| | Task Manager | | Interrupt Handler (ISR) | |

| +-------------------+ +-------------------------+ |

| | | |

| +-------------------+ +-------------------------+ |

| | Scheduler | | Inter-Process Comm. | |

| +-------------------+ +-------------------------+ |

| | | |

| +-------------------+ +-------------------------+ |

| | Device Drivers | | Timers & Clocks | |

| +-------------------+ +-------------------------+ |

+--------------------------------------------------------+

|

v

Sensors & Actuators (Robot Hardware)

Integration Points with CI/CD or Cloud Tools

- CI/CD: RTOS code can be integrated into CI/CD pipelines using tools like Jenkins or GitLab CI to automate testing and deployment. Unit tests for tasks and integration tests for hardware interactions ensure reliability.

- Cloud Tools: RTOS-based robotic systems can connect to cloud platforms (e.g., AWS IoT) via middleware like FreeRTOS’s AWS integration for data logging and remote updates.

- Simulation: Tools like Webots integrate with RTOS to simulate robotic behavior before deployment.

Installation & Getting Started

Basic Setup or Prerequisites

To set up an RTOS for RobotOps, you’ll need:

- Hardware: A microcontroller (e.g., ARM Cortex-M, Raspberry Pi) with sufficient RAM/ROM.

- Development Environment: IDE like Keil uVision, Eclipse, or VS Code with RTOS support.

- RTOS Distribution: FreeRTOS, Zephyr, or VxWorks (depending on the project).

- Toolchain: Compiler (e.g., GCC for ARM) and debugger (e.g., JTAG).

- Dependencies: USB drivers, board-specific libraries, and RTOS documentation.

Hands-On: Step-by-Step Beginner-Friendly Setup Guide (FreeRTOS Example)

This guide demonstrates setting up FreeRTOS on an STM32 microcontroller using STM32CubeIDE.

- Install STM32CubeIDE:

- Download and install STM32CubeIDE from STMicroelectronics’ website.

- Ensure the STM32CubeMX plugin is installed for hardware configuration.

- Create a New Project:

- Open STM32CubeIDE, select “File > New > STM32 Project.”

- Choose your STM32 board (e.g., STM32F4).

- Configure the project with default settings (e.g., clock speed, GPIO).

- Integrate FreeRTOS:

- In STM32CubeMX, go to “Pinout & Configuration” > “Middleware” > “FreeRTOS.”

- Enable FreeRTOS and select CMSIS-RTOS V2 API for compatibility.

- Configure heap size (e.g., 4 KB) and stack size for tasks.

- Write a Simple Task:

#include "FreeRTOS.h"

#include "task.h"

void Task1(void *pvParameters) {

while (1) {

// Simulate sensor reading

printf("Task 1: Reading sensor\n");

vTaskDelay(pdMS_TO_TICKS(1000)); // Delay 1 second

}

}

int main(void) {

// Initialize hardware

HAL_Init();

// Create task

xTaskCreate(Task1, "SensorTask", 128, NULL, 1, NULL);

// Start scheduler

vTaskStartScheduler();

while (1);

}5. Build and Flash:

- Build the project in STM32CubeIDE.

- Connect the STM32 board via USB and flash the firmware using the IDE’s debugger.

- Monitor output via a serial terminal (e.g., PuTTY).

6. Test:

- Verify that “Task 1: Reading sensor” prints every second.

- Add more tasks (e.g., motor control) to test multitasking.

Real-World Use Cases

Scenario 1: Industrial Robotic Arm

- Application: A robotic arm welds car bodies in an automotive assembly line.

- RTOS Role: Ensures hard real-time performance to synchronize arm movements with conveyor belt timing, avoiding defects.

- Example: VxWorks RTOS controls task priorities to ensure precise timing for servo motors.

Scenario 2: Autonomous Drone Navigation

- Application: A drone navigates using real-time sensor data (e.g., LiDAR, GPS).

- RTOS Role: Processes sensor inputs and adjusts flight paths within milliseconds, ensuring collision avoidance.

- Example: Zephyr RTOS, with its networking stack, integrates sensor data with cloud-based navigation updates.

Scenario 3: Medical Robot (Surgical Assistant)

- Application: A robotic system assists in precision surgeries.

- RTOS Role: Guarantees deterministic responses for real-time feedback from sensors and actuators, critical for patient safety.

- Example: QNX Neutrino RTOS ensures reliability and compliance with medical standards.

Industry-Specific Example: Automotive (AUTOSAR)

- Application: Anti-lock braking systems (ABS) in vehicles.

- RTOS Role: AUTOSAR-compliant RTOS (e.g., OSEK) manages real-time tasks for brake control, ensuring rapid response to wheel slip.

Benefits & Limitations

Key Advantages

- Deterministic Performance: Ensures tasks meet strict deadlines, critical for RobotOps.

- Resource Efficiency: Optimized for low-memory embedded systems.

- Scalability: Supports simple to complex applications, from sensors to multi-core systems.

- Reliability: Robust for safety-critical applications like robotics and automotive.

Common Challenges or Limitations

- Complexity: Steep learning curve for configuring and optimizing RTOS.

- Limited Features: Lacks the flexibility of GPOS for non-real-time tasks.

- Cost: Commercial RTOS like VxWorks may involve licensing fees.

- Debugging: Long ISRs or priority inversions can be hard to debug.

| Aspect | Benefits | Limitations |

|---|---|---|

| Performance | Deterministic, low-latency responses | Limited to time-critical tasks |

| Resource Usage | Minimal memory and CPU footprint | Not suited for feature-rich applications |

| Cost | Free options like FreeRTOS available | Commercial RTOS can be expensive |

| Debugging | Trace tools for performance analysis | Complex to debug priority issues |

Best Practices & Recommendations

Security Tips

- Secure Boot: Use RTOS with secure boot (e.g., Zephyr) to prevent unauthorized firmware.

- Memory Protection: Leverage memory management units (MMUs) to isolate tasks.

- Regular Updates: Apply patches for known vulnerabilities in open-source RTOS.

Performance

- Minimize Context Switching: Reduce task switching overhead by optimizing priorities.

- Short ISRs: Keep interrupt service routines concise to avoid blocking high-priority tasks.

- Profile Tasks: Use tools like Percepio Tracealyzer to monitor task timing.

Maintenance

- Modular Design: Break applications into independent tasks for easier updates.

- Logging: Implement logging for task states and errors to aid debugging.

- Version Control: Use Git for RTOS code to track changes and roll back if needed.

Compliance Alignment

- Safety Standards: Choose RTOS certified for standards like ISO 26262 (automotive) or DO-178C (aerospace).

- Documentation: Maintain detailed task and scheduling documentation for audits.

Automation Ideas

- CI/CD Integration: Automate RTOS builds and tests using Jenkins or GitHub Actions.

- Simulation: Use simulators like Webots to test RTOS-based robotic applications before deployment.

Comparison with Alternatives

| Feature | RTOS | GPOS (e.g., Linux) | ROS (Robot Operating System) |

|---|---|---|---|

| Real-Time Performance | Deterministic, low-latency | Non-deterministic, high-latency | Not real-time, but ROS 2 supports RTOS integration |

| Resource Usage | Minimal (few MBs) | High (20+ GB) | Moderate (depends on middleware) |

| Use Case | Embedded systems, robotics | General computing, servers | Robotics middleware, not an OS |

| Complexity | Moderate, task-focused | High, feature-rich | High, requires RTOS for real-time |

| Examples | FreeRTOS, VxWorks, QNX | Ubuntu, Windows | ROS, ROS 2 |

When to Choose RTOS

- Choose RTOS: For time-critical robotic applications requiring deterministic responses (e.g., motor control, sensor processing).

- Choose GPOS: For non-real-time tasks like user interfaces or data logging in robotics.

- Choose ROS: For high-level robot software development, integrated with an RTOS for real-time tasks.

Conclusion

RTOS is a cornerstone of RobotOps, enabling precise, reliable, and efficient management of robotic systems. Its deterministic nature, resource efficiency, and scalability make it ideal for applications ranging from industrial robots to autonomous vehicles. While challenges like complexity and cost exist, best practices in security, performance, and maintenance can mitigate these issues. As robotics and IoT continue to evolve, RTOS will play an increasingly vital role, with advancements like ROS 2 integration and cloud connectivity shaping the future.

Next Steps

- Explore FreeRTOS or Zephyr for open-source projects.

- Experiment with RTOS on a microcontroller using the setup guide provided.

- Join RTOS communities for support and updates.